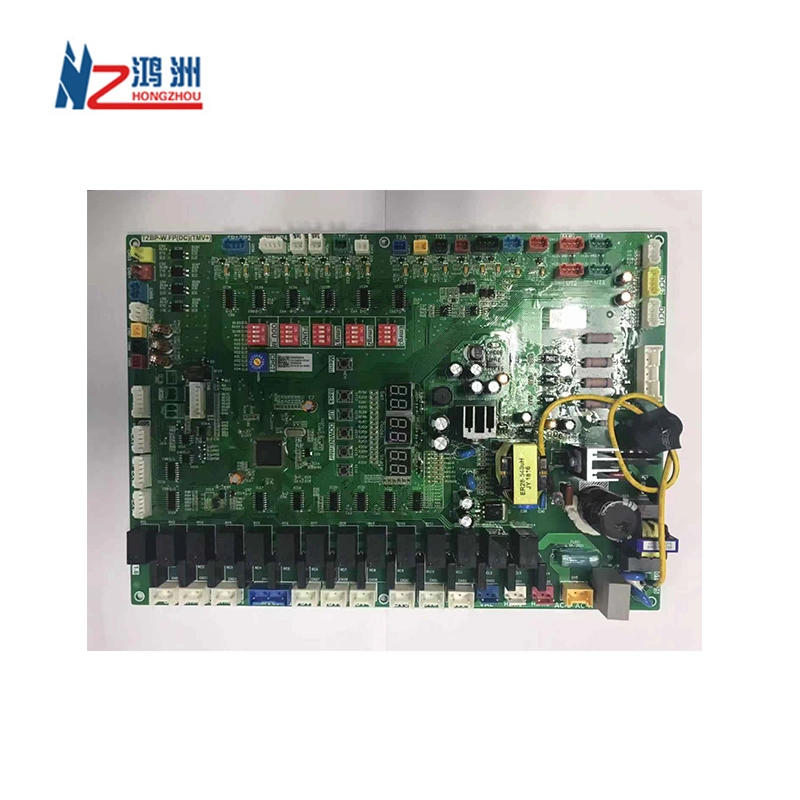

PCBA service pcba manuafcturing Electronic Printed Circuit Board Mature Smt Dip Assembly Pcba Board Technology Manufacturer From

- Supplier Type:

-

Manufacture

- Model Number:

-

HZ2020011

- Place of Origin:

-

Guangdong, China

- Layer::

-

1-40 layer

- Copper thickness::

-

0.25 Oz -12 Oz

- Material::

-

FR-4,Halogen free,High TG,Cem-3,PTFE,Aluminum BT,Rogers

- Board thickness:

-

0.1 to 6.0mm(4 to 240mil)

- Minimum line width/space:

-

0.076/0.076mm

- Outer layer copper thickness:

-

140um(bulk) 210um(pcb prototype)

- Inner layer copper thickness:

-

70um(bulk) 150um(pcb protytype)

- Min.finished hole size(Mechanical):

-

0.15mm

- Min.finished hole size (laser hole):

-

0.1mm

- Solder Mask Color:

-

Green,Blue,Black,White,Yellow,Red,Grey

Online Customization

Shenzhen Hongzhou Smart Technology Co.Ltd was founded in 2005,we are a manufacturer who are specialized in PCB Assembly (SMT, DIP, AI) and electronic product final assembly (EMS) in the top market for global customers.

We have more than 10 years of SMT manufacturing experience, well appointed SMT ,DIP and assembly lines, offering one stop service from SMT,FPC,DIP,EMS, conformal coating, testing, final assembly, component procurement ,design, peripheral products support and so on. we are equipped with High-speed and accurately SMT Equipment ,and we provide a whole range of SPI,AOI,ICT,FCT,X-RAY,ROHS and aging testing for products. All ourshop floors are dust free, all lines are lead free, we are ISO9001 certified company.

We offer high quality PCB & PCBA Service for Industrial control Board, Financial Industrial Board, Automatic PCBs, New enery controller PCBAs, Medical equipment printed circuits and other high level circuit boards.

We offer one-stop service for PCB , including PCB manufacturing, parts sourcing, X-RAY, AOI testing, Function testing, final assembly if requested.

FAQ

Q1:What is needed for quotation

·PCB: Quantity, Gerber file and Technic requirements(material,surface finish treatment, copper thickness,board thickness ,...)

·PCBA: PCB information, BOM, (Testing documents...)

Full assembly product: PCBA Information and product buidinformation

Q2:. Are you a manufacture?

Yes,we are. Warmly welcome to visit our factory at any time

Q3. Are my files safe?

Your files are held in complete safety and security.We protect the intellectual property for our customers in the whole process.. All documents from customers are never shared with any third parties.

Q4; What is the delivery time?

Normal: 5-7 workingdays for samples, 7-25working days for bulk production.

For Urgent project: We can arrange preferential processing and control the delivery time as you request

Q5. Do you have MOQ?

There is no MOQ.We are able to handle Small as well as large volume production with flexibility.

Q6: What is the payment term?

100%T/T in advance normally;50% deposit,50% balance by T/T before shipment

Q7. Shipping cost?

The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the shipping cost.