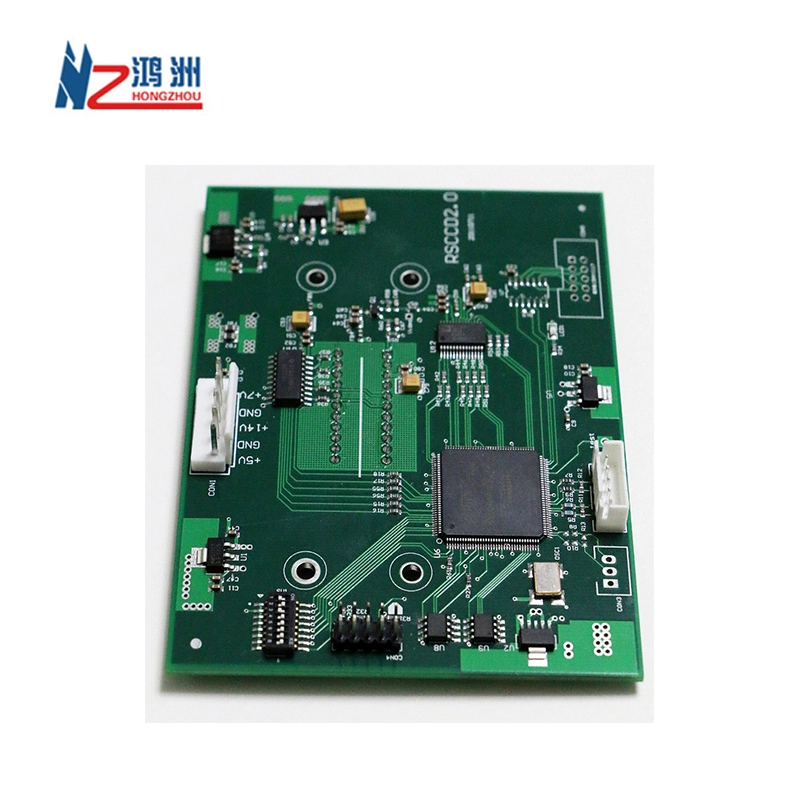

Hotsale Custom PCB assembly PCBA Service

- Model Number:

-

HZ-PCB033

- Place of Origin:

-

Guangdong, China

- Min. Line Width:

-

0.1mm(Flash Gold)/0.15mm(HASL)

- Copper Thickness:

-

1/2OZ 1OZ 2OZ 3OZ

- Brand Name:

-

OEM/ODM

- Min. Line Spacing:

-

0.1mm4mil)

- Board Thickness:

-

1.6mm-3.2mm

- Base Material:

-

FR-4

- Surface Finishing:

-

HASL

- Min. Hole Size:

-

0.075mm(3mil)

- Product name:

-

Hotsale Custom PCB assembly PCBA Service

- Material:

-

FR4 /aluminum/ceramicCEM1

- Application:

-

Communications

- Certificate:

-

ISO/UL/RoHS/TS16949

- Usage:

-

Car Controller

- Solder mask:

-

Green. Red. Blue. White. Black.Yellow

- Type:

-

Customizable

- Layer(MAX):

-

1-48

- Sample:

-

Available

- Services:

-

one-stop services

- Supply Ability:

- 100000 Piece/Pieces per Month

Online Customization

Hotsale Custom PCB assembly PCBA Service

| Article | Description | Capability |

| Material | Laminate materials | FR4,Alu,CEM3,Taconic,Rogers |

| Board cutting | Number of layers | 1-58 |

| Min. Thickness for inner layers | 0.003”(0.07mm) | |

| (Cu thickness are excluded) | ||

| Board thickness | Standard | 0.04-0.16”±10%(0.1-4mm±10%) |

| Min. | Single/Double layer: 0.008±0.004” | |

| 4 layer: 0.01±0.008” | ||

| 8 layer: 0.01±0.008” | ||

| Bow and twist | <7/1000 | |

| Copper weight | Outer Cu weight | 0.5-4 oz |

| Inner Cu weight | 0.5-3 oz | |

| Drilling | Min size | 0.0078” (0.2mm) |

| Drill deviation | ±0.002” (0.05mm) | |

| PTH hole tolerance | ±0.002” (0.005mm) | |

| NPTH hole tolerance | ±0.002” (0.005mm) | |

| Plating | Min hole size | 0.0008” (0.02mm) |

| Aspect ratio | 20 (5:1) | |

| Solder mask | Color | Green,white,black,red,yellow,blue... |

| Min solder mask clearanace | 0.003” (0.07mm) | |

| Thickness | 0.0005-0.0007”(0.012-0.017mm) | |

| Silkscreen | Color | White,black,yellow,red,blue... |

| Min size | 0.006” (0.15mm) | |

| E-test | Flying Probe Tester | Y |

| Controlled Impedance | Tolerance | ±10% |

| Impedance tester | Tektronix TDS8200 | |

| Surface Finish | HASL,ENIG,immersion silver,immersion tin,OSP... | |

| EMS-Electronic Manufacturing Service |

| PCB Supply and Layout |

| PCB Assembly on SMT, BGA and DIP |

| Cost Effective Components Sourcing |

| Fast Turn Prototype and Mass Production |

| Box Build Assembly |

| Engineering Support |

Tests(X-ray, 3D Paste Thickness, ICT, AOI and Functional tests) |

| Logistics and After-sales Service |

| Our advantage: |

| 1. Our company through TS16949: 2009 quality system certification,exports of processed products comply with European standards |

| 2. There is no minimum order quantity restrictions, full support from proofing to batch. |

| 3. Professional component sourcing team, centralized purchasing, you save procurement costs, labor costs, quality costs. |

| 4. Fast Proofing: SMT samples 24 hours of delivery. |

| 5. Our main customer groups: medical, industrial, security, communications, electricity and other high-end |

6.Shenzhen Jingbang technology in the "customers want a little more for our customers to do more to root for quality, service-oriented" service purposes. |

| FAQ | |

| Q: How to Get a quotation? | |

A: Please send us more RFQ details(such as GERBER File,BOM(bill of Material),sample/pictures, Forecast or Quantity Reference etc.) | |

| Q: What’s your MOQ for PCBA? | |

A: No MOQ for PCBA. We can do prototype and mass production as well. There exists Economical Order Quantity (EOQ), Please send inquiry to us for details. | |

| Q: Can you do turnkey services? Can you procure all parts in BOM for us? | |

| A:Due to MOQ & MPQ of Components, it depends on order quantity: | |

| *We would like to process the BOM procurement for MP(Mass Production) | |

*We prefer Customer to supply components for Prototype and Pilot-run order Please send inquiry to us for more details. | |

| Q: What’s your L/T for PCBAs? | |

A: PCBA Lead Time is normally 2 weeks. Post Test and Box build might last the Lead Time longer to 3 weeks Precise Instructions, SOP and Fine Test Fixture could expedite the L/T. | |

| Q:Will the boards be tested before shippment? | |

| A: For PCBA,we will have AOI,X-ray,and functional test. |