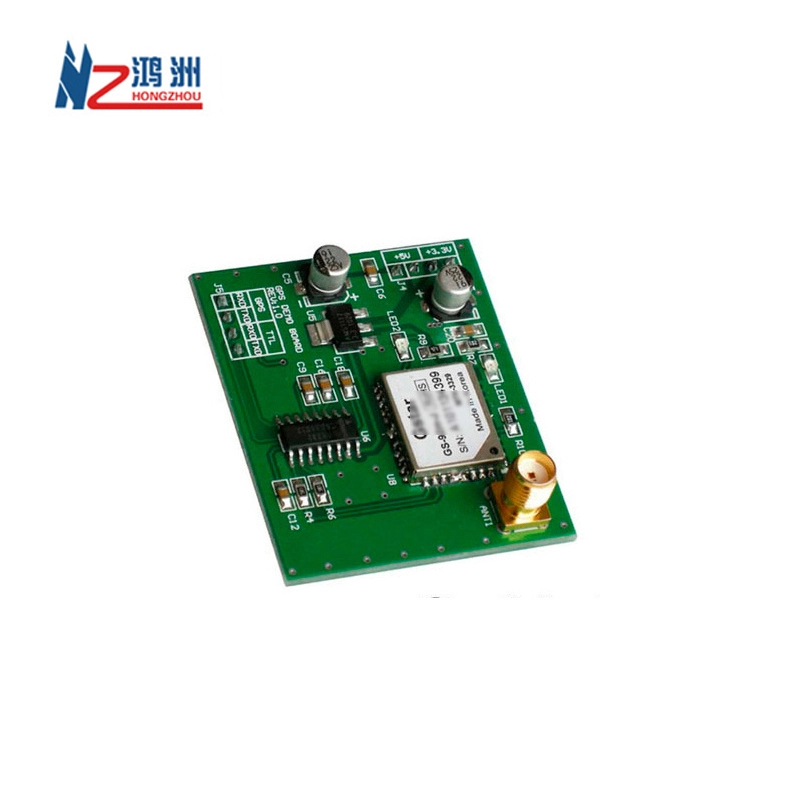

OEM Electronic PCBA Multilayer Flexible PCB Assembly

- Model Number:

-

HZ-PCB017

- Place of Origin:

-

Guangdong, China

- Product name:

-

OEM Electronic PCBA Multilayer Flexible PCB Assembly

- Material:

-

FR4 CEM1 CEM3 Hight TG

- Application:

-

Communications

- Certificate:

-

ISO/TS16949/RoHS

- Type:

-

Customizable

- Usage:

-

OEM Electronics

- Solder mask:

-

Green. Red. Blue. White. Black.Yellow

- Item:

-

ODM OEM LED PCBA

- Solder mask color:

-

Black.Red.Yellow.White.Blue.Green

- Quality control:

-

100% QC inspection before shipping

- Brand Name:

-

OEM/ODM

- Base Material:

-

FR-4

- Copper Thickness:

-

0.25 Oz -12 Oz

- Board Thickness:

-

1.6mm-3.2mm

- Min. Hole Size:

-

0.075mm(3mil)

- Min. Line Width:

-

0.1mm(Flash Gold)/0.15mm(HASL)

- Min. Line Spacing:

-

0.1mm4mil)

- Surface Finishing:

-

HASL Lead

- Supply Ability:

- 100000 Piece/Pieces per Month

Online Customization

OEM Electronic PCBA Multilayer Flexible PCB Assembly

OEM & ODM Orders are Welcome.

We have in-house workshop for one stop shop service

OEM (We manufacture according to your design - BOM, Gerber file and testing procedures, while providing you best recommendations for easy manufacturing and cost saving):

1. Component sourcing and procurement

2. PCB Manufacturing

3. Component Assembly (PCBA - SMT & Through Hole parts)

4. Chip-on-board (COB)

Surface-mount technology (SMT)

Ball-grid array (BGA)

Through-hole

5. Plastic Enclosure (Mould) Manufacturing

6. Metal Enclosure (Tool) Manufacturing

7. Cable & Wire harness Assembly

8. Final Assembly

9. QC Testing

10.Packaging

|

1 |

Layers |

Single Sided,2 to 18 Layer |

|

2 |

Board material type |

FR4,CEM-1,CEM-3,ceramic substrate board, aluminum based board, high-Tg, Rogers and more |

|

3 |

Compound material lamination |

4 to 6 layers |

|

4 |

Maximum dimension |

610 x 1,100mm |

|

5 |

Dimension tolerance |

±0.13mm |

|

6 |

Board thickness coverage |

0.2 to 6.00mm |

|

7 |

Board thickness tolerance |

Board thickness≤1.0mm: +/-0.1mm |

|

8 |

DK thickness |

0.076 to 6.00mm |

|

9 |

Minimum line width |

0.10mm |

|

10 |

Minimum line space |

0.10mm |

|

11 |

Outer layer copper thickness |

8.75 to 175µm |

|

12 |

Inner layer copper thickness |

17.5 to 175µm |

|

13 |

Drilling hole diameter (mechanical drill) |

0.25 to 6.00mm |

|

14 |

Finished hole diameter (mechanical drill) |

0.20 to 6.00mm |

|

15 |

Hole diameter tolerance (mechanical drill) |

0.05mm |

|

16 |

Hole position tolerance (mechanical drill) |

0.075mm |

|

17 |

Laser drill hole size |

0.10mm |

|

18 |

Board thickness and hole diameter ratio |

10:01 |

|

19 |

Solder mask type |

Green, Yellow, Black, Purple, Blue, White and Red |

|

20 |

Minimum solder mask |

Ø0.10mm |

|

21 |

Minimum size of solder mask separation ring |

0.05mm |

|

22 |

Solder mask oil plug hole diameter |

0.25 to 0.60mm |

|

23 |

Impedance control tolerance |

±10% |

|

24 |

Surface finish |

Hot air level, ENIG, immersion silver, gold plating, immersion tin and gold finger |

|

25 |

Certificate |

ROHS, ISO9001:2008, SGS, UL certificate |

|

26 |

Acceptable file format |

Gerber file,PROTEL series,PADS series,POWER PCB series,AutoCAD |